Analysison Straightening Seamless Steel Pipe

The straightening process is generally used to eliminate the longitudinal bending and the roundness error of the rolled seamless steel pipe. It determins their genmetrical sizes and influences their mechanical properties. The mechanical mode

Analysison Straightening Seamless Steel Pipe Description

Rolled and drawed Stainless steel seamless pipe will have the longitudinal bending and the roundness error. These defects can be eliminated by straightening process. So, Straightening process decide not only geometrical sizes, but also affect the mechanical properties. During course of straightening, the longitudinal bending and roundness error can be eliminated by properly adjustment to straightness equipment and improved the mechanical properties.

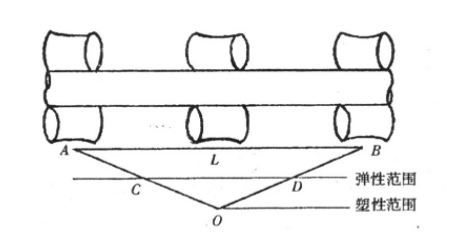

For our plant,besides bending straightening (by raising the middle roll), a radial pressure is applied between the upper and lower straightening rolls. If the distance between the straightening rollers at both ends (i.e. the support distance) is SET as L, then the elastic and plastic deformation zones are included in the range of L. Generally, the length of plastic deformation zone is about 40% of L. Bending of steel pipe along COD curve is shown in FIG. 1. But the CA and BD parts are in the elastic deformation zone, so no straightening is achieved. The deformation at point O is the largest, so a bending curvature equal to or slightly larger than its original curvature should be given at this point (i.e. the middle roll) to straighten the steel pipe.

In the straightening process, the forward speed of steel pipe is directly affected by the Angle of the straightening roll. As shown, the straightening roll speed, through contact with the steel tube is passed to the steel tube, if set of straightening roll the middle cross section on radial force is p, when p force to the steel pipe surface, for steel tube is decomposed into two forces, one is to make the steel pipe rotation around its axis force of p1, another is to make the steel pipe along its axis direction of P2. According to the mechanical principle, P1, P2 and inclination Angle A are related as follows:

tan A = P2/P1

In P1 force, under the action of steel tube around the axis of rotation, revolves the distance for Pd, for steel pipe diameter (d), as it rotates, P2 force to make steel tube S forward distance, this week S rotation of the steel tube straightening distance, S = Pd tanA, thus it can be seen that the same specifications diameter steel tube, under the condition of straightening speed is constant, The greater the included Angle between the straightening roller and the steel tube axis, the faster the straightening speed. However, the rotation speed of the tube is reduced, that is, the number of times the tube is bent is reduced.

With the mind of being better, we are doing step by step.

Related Stainless steel seamless tube

Piercing Bar-The first step of quality control

Small crack are offen ignored. In order to improve the appearance quality, we need to do fully grinding for piercing ba...

Process of Stainless Steel Seamless Pipe

Process is the soul of production. Good or bad product can be judged by the appearance. How do we do to escape the defe...

Analysison Straightening Seamless Steel Pipe

The straightening process is generally used to eliminate the longitudinal bending and the roundness error of the rolled s...

Improved Pipe Appearance, Enlarged the Market

Inner beauty need to show by outer surface. The improving of pipe appearance is the kep step to prolong service time....

TP904L/UNS N08904

TP904L is a low carbon, high alloying austenitic stainless steel material designed for harsh corrosion conditions. It has...

UN S31803/ UN S32205 Duplex Stainless Steel Pipe

Austenitic-ferritic Duplex stainless steel pipe roughly has the same proportion both austenite and ferrite phase. Austeni...